Born Recycled: Turning waste into opportunities

Sustainability and the circular economy are increasingly urgent issues in today’s world. With this commitment in mind, Nautilus, an innovative company in the field of education, has joined forces with Fibrenamics to create the Born Recycled project – an initiative that gives new life to waste by transforming it into sustainable and durable products.

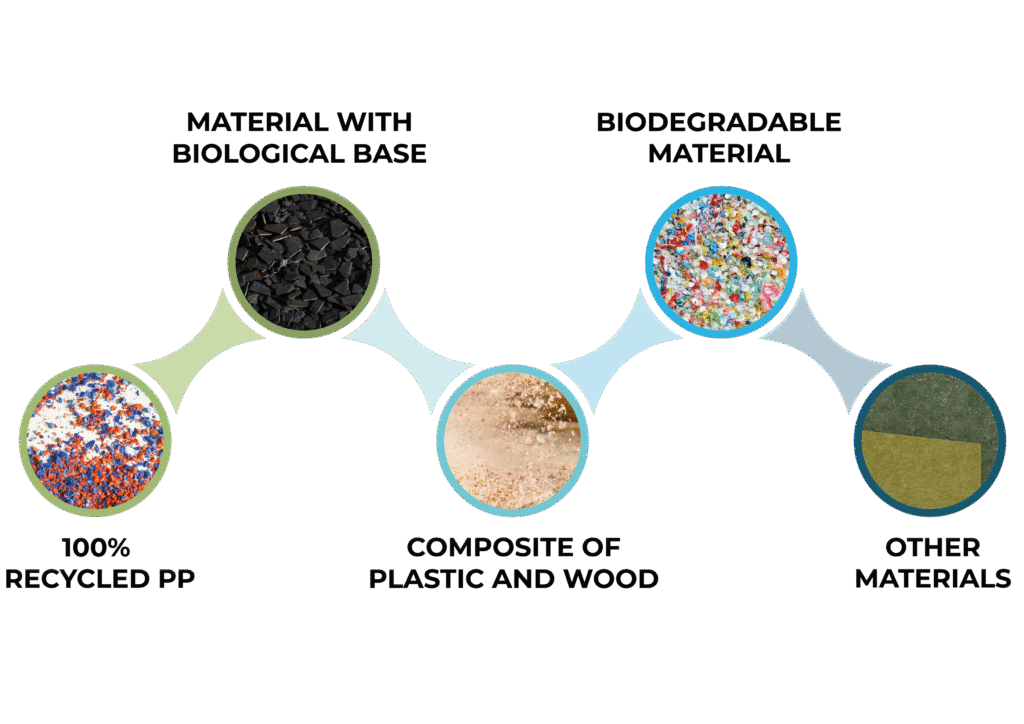

The main purpose of this project is to establish a closed production cycle, where discarded materials are reused in an intelligent and innovative way. Waste from different production sectors, such as polymers (pre- and post-consumer), carpentry scraps and even slate, are carefully reintegrated into the production process. This avoids landfills and incineration, maximising the value of materials and significantly reducing the environmental footprint.

Born Recycled represents an essential step in the search for more sustainable solutions, proving that it is possible to combine innovation and environmental responsibility.

After all, the future of production lies in transforming waste into new opportunities.

What is discarded today

becomes tomorrow’s product

The Injection Moulding Process: 40% Recycled Polymer

In the first phase of the project, the focus is on developing a material for the injection moulding process that uses 40% recycled polymer. The polymer material, sourced from post-consumer products and pre-consumer industrial waste, is treated and transformed into granules, which are then mixed with woodworking and slate waste that has also been treated and transformed into granules. The big challenge is to ensure that this mixture maintains its mechanical properties without compromising the aesthetics and quality of the final product.

The Compression Moulding Process: 80% Recycled Polymer

At the same time, the team of engineers and designers is also working on creating the same material, but one that is more suited to the compression moulding process and incorporates an even higher percentage of recycled polymer. The goal is to achieve 80% recycled polymer in the composition of the new material.

Nautilus and Fibrenamics have adopted a holistic approach, where each stage of the product life cycle is designed to minimise environmental impact. From the choice of materials, through the manufacturing process to the disposal of raw materials – everything has been designed to ensure that as little waste as possible is generated.

The products created within the scope of the project will be 100% recyclable.

At the end of their useful life, they can be dismantled, separated and reintegrated into the production cycle.

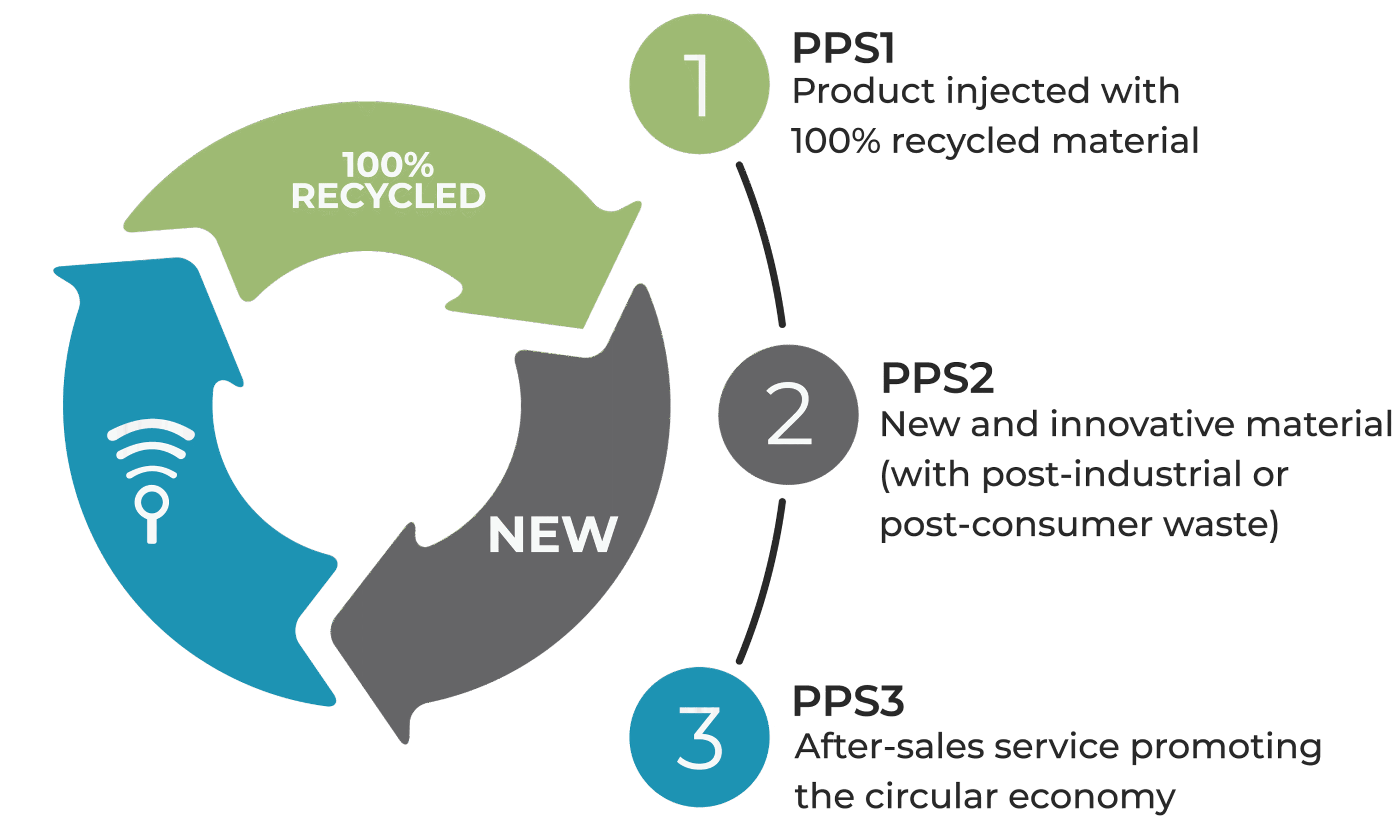

Born Recycled Product Life Cycle

In the Born Recycled project, product life cycle management is carried out through the incorporation of information technology that allows data to be recorded on the origin of materials, manufacturing processes, technical specifications, recycling instructions and other information, functioning as a digital passport for each product.

When the product reaches the end of its useful life, the information in the digital passport facilitates the identification of components so that they can be reintegrated into the production cycle, in line with the aforementioned ‘cradle-to-cradle’ concept. This technology thus enables complete and secure traceability, ensuring the sustainable circularity of each product manufactured and reinforcing the environmental commitment of Nautilus and Fibrenamics.

Potential new products